Industrial Visit at Internatio

.jpeg)

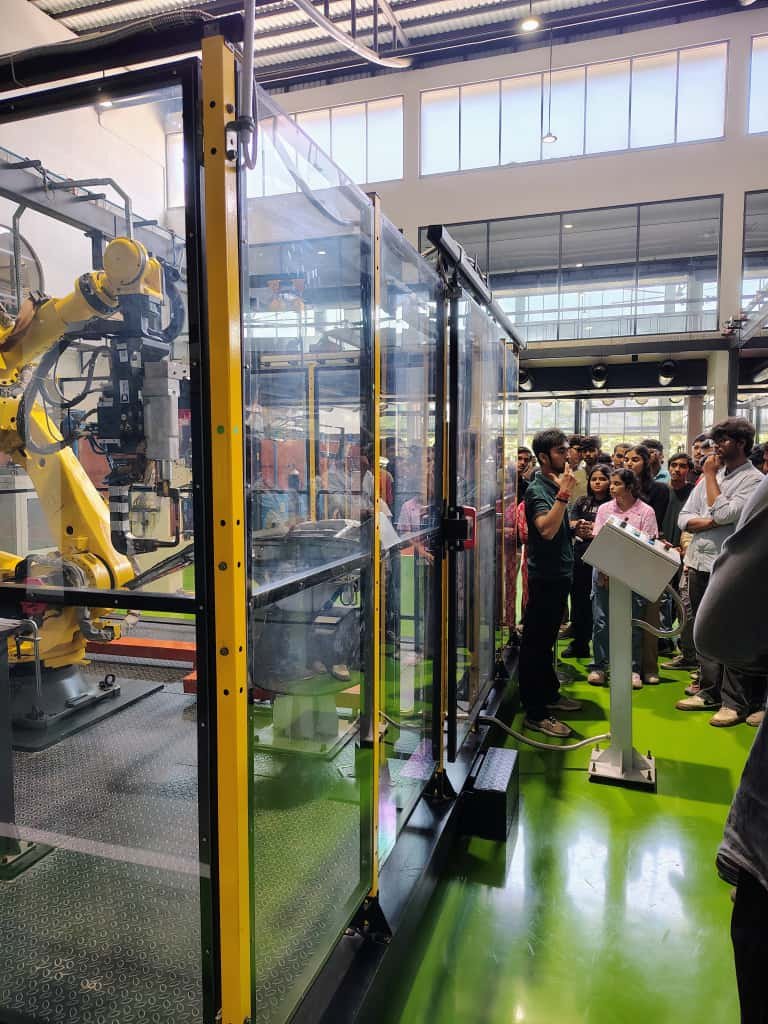

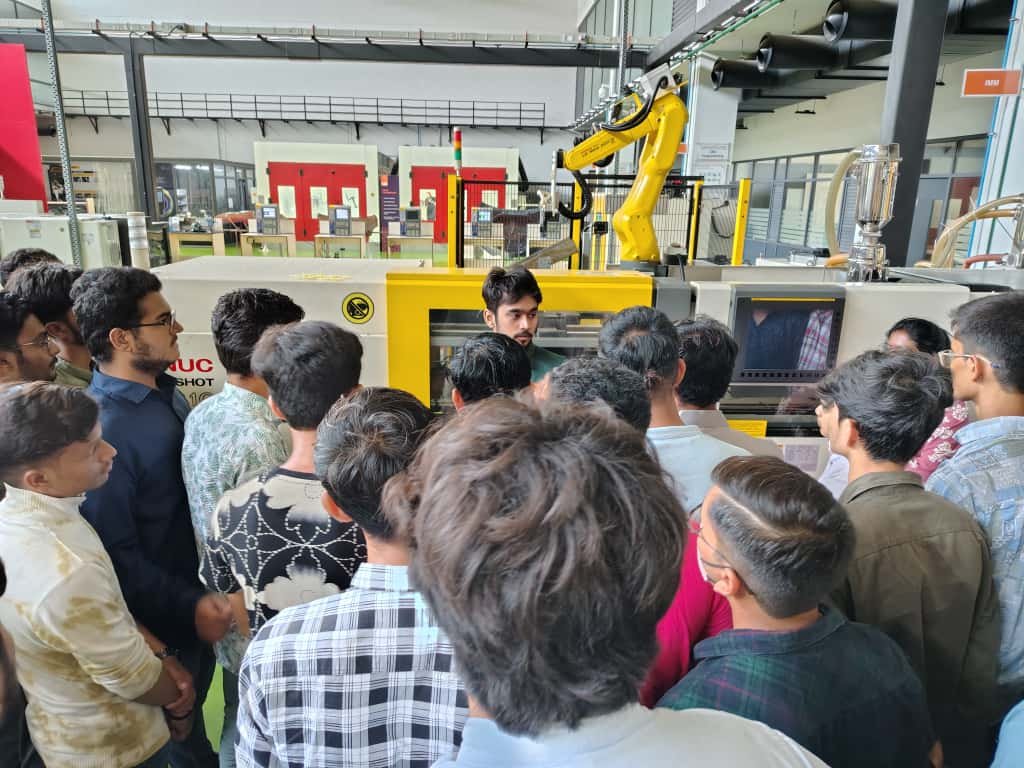

The industrial visit to the International Automobile Centre of Excellence (iACE), Gandhinagar, offered fifth-semester Mechanical and Aeronautical Engineering students from Gyanmanjari Institute of Technology an enriching exposure to modern automotive technologies and industry practices. Established through a collaboration between the Government of Gujarat and Maruti Suzuki, iACE serves as a premier hub for automotive skill development, featuring advanced labs, EV training modules, diagnostic tools, and state-of-the-art manufacturing and testing facilities. Through guided tours, live demonstrations, and expert interactions, students gained practical insights into electric mobility, vehicle diagnostics, automation, and sustainable transportation. The visit effectively bridged the gap between theoretical knowledge and real-world applications, familiarizing students with evolving industry trends and career opportunities. Overall, the experience enhanced their technical competence, encouraged innovation, and prepared them to contribute meaningfully to the rapidly transforming automotive and mobility ecosystem.

Industrial Visit at Siddhpura

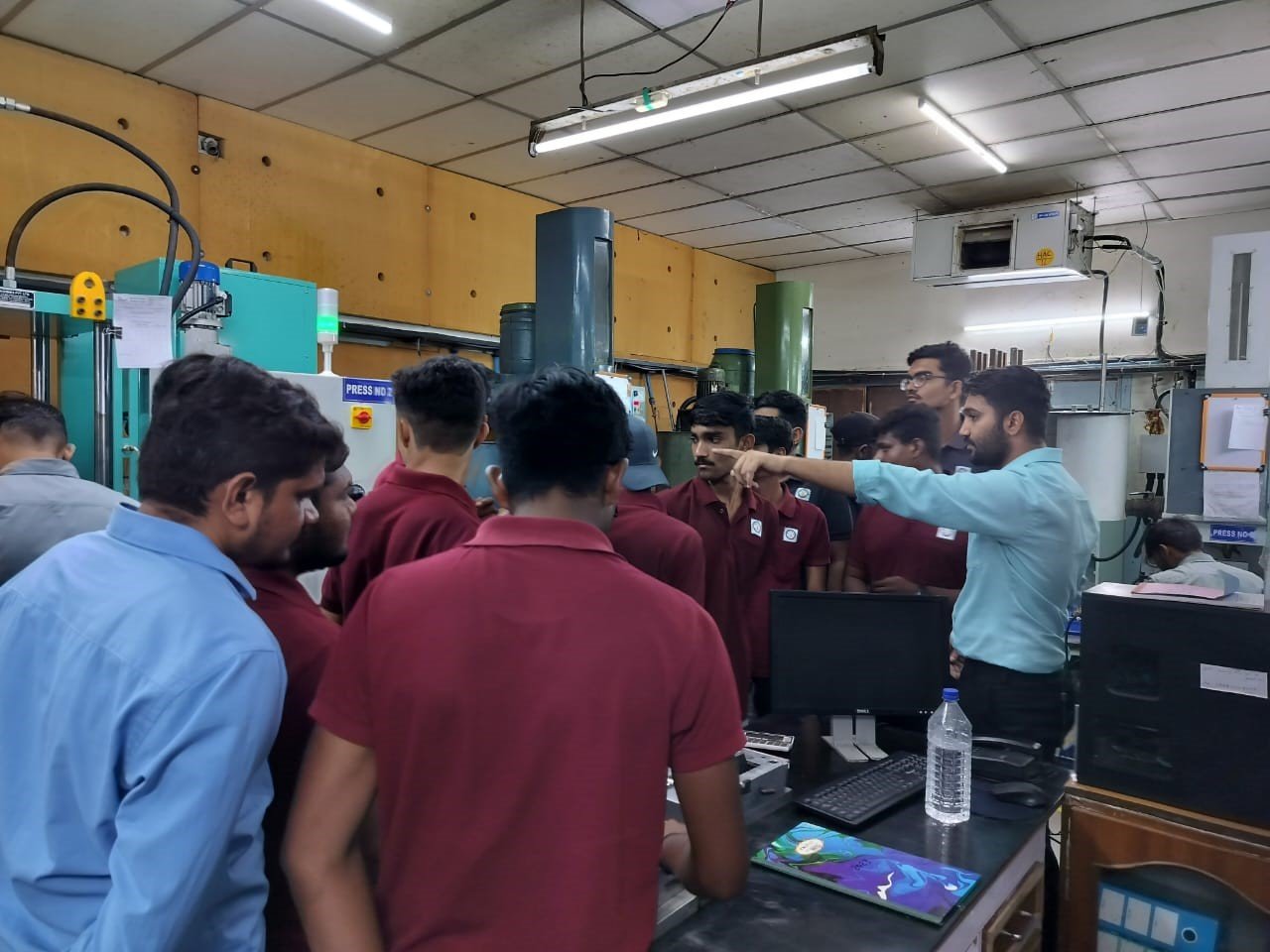

Faculties Jigar K. Andharia and Priyank P. Gohil led a group of students on an enriching industrial visit to Siddhapura Machine Tools in Bhavnagar, Gujarat. As a well-established company known for its high-quality industrial machines, Siddhapura Machine Tools offered an ideal platform for the students to observe firsthand the sophisticated manufacturing practices used to produce machinery that meets both domestic and international standards.

During the visit, students were introduced to the various stages of production, from raw material handling to final assembly. They were able to witness how Siddhapura Machine Tools handles bulk orders while maintaining strict adherence to customer specifications. The highlight of the visit was the opportunity to observe the company’s stringent quality control procedures. Each component and machine undergoes rigorous testing, and the students were able to interact with the quality assurance team, gaining insights into the processes that ensure product reliability, performance, and compliance with regulatory standards.

Both faculties, Jigar K. Andharia and Priyank P. Gohil, provided valuable guidance throughout the visit, helping students link theoretical concepts from their academic coursework to the practical applications they were witnessing. The interaction with the company’s engineers and quality analysts further enriched the students’ understanding of the challenges faced in the industry and how advanced solutions are implemented to overcome them.

Additionally, the visit served as a platform for students to explore potential career paths in mechanical engineering, manufacturing, and quality assurance. The exposure to industrial equipment and the operational environment helped broaden their understanding of the skills and knowledge required in these fields. Overall, the visit to Siddhapura Machine Tools was a highly informative and practical experience, enhancing the students' academic learning and preparing them for future roles in the industrial sector.

Industrial Visit at Carriage R

A group of 35 students, led by faculty members Mr. Jigar Andharia and Ms. Noopur Vyas, embarked on an educational visit to the Carriage Repair Workshop in Bhavnagar Para, Gujarat. The purpose of this visit was to provide students with hands-on exposure to the inner workings of a major industrial facility and to supplement their academic knowledge with real-world industrial practices.

Upon arriving at the workshop, the group was warmly greeted by the staff, who provided an introductory briefing about the workshop’s history, operations, and its critical role within the Indian Railways. After the briefing, the group was taken on a guided tour of the facility. The students observed various sections, including the bogie repair area, brake testing unit, and the painting and refurbishment stations. Each section showcased different aspects of carriage maintenance, from mechanical repairs to detailed refurbishments.

Throughout the visit, both Mr. Jigar Andharia and Ms. Noopur Vyas actively engaged with the workshop technicians, facilitating an interactive learning experience for the students. They encouraged students to ask questions and gain a deeper understanding of the technical processes involved in carriage repair. The technicians also provided insightful demonstrations on how specific components like wheels, brakes, and suspensions are maintained and inspected for safety. One of the most memorable parts of the visit was witnessing the quality assurance tests performed on repaired carriages. Students were able to see firsthand the rigorous safety checks that each carriage undergoes before being cleared for service on the railways. The visit concluded with an informative Q&A session, where the workshop staff answered questions raised by the students and faculty. The experience offered a unique glimpse into the operations of one of Indian Railways’ critical maintenance facilities, giving the students a practical perspective on the complexities involved in maintaining a large-scale rail network.

Overall, the visit was an enriching experience for the students, allowing them to connect theoretical learning with practical applications. Both Mr. Jigar Andharia and Ms. Noopur Vyas expressed their satisfaction with the visit, highlighting its value in expanding the students’ understanding of industrial processes.

Industrial Visit at ISRO, Ahme

Indian Space Research Organisation (ISRO) is the space agency of India. The organisation is involved in science, engineering and technology to the benefits of outer space for India and the mankind. ISRO is a major constituent of the Department of Space (DOS), Government of India. The department executes the Indian Space Programmeprimarily through various Centres or units within ISRO.

ISRO was previously the Indian National Committee for Space Research (INCOSPAR), set up by the Government of India in 1962, as envisioned by Dr. Vikram A Sarabhai. ISRO was formed on August 15, 1969 and superseded INCOSPAR with an expanded role to harness space technology. DOS was set up and ISRO was brought under DOS in 1972.

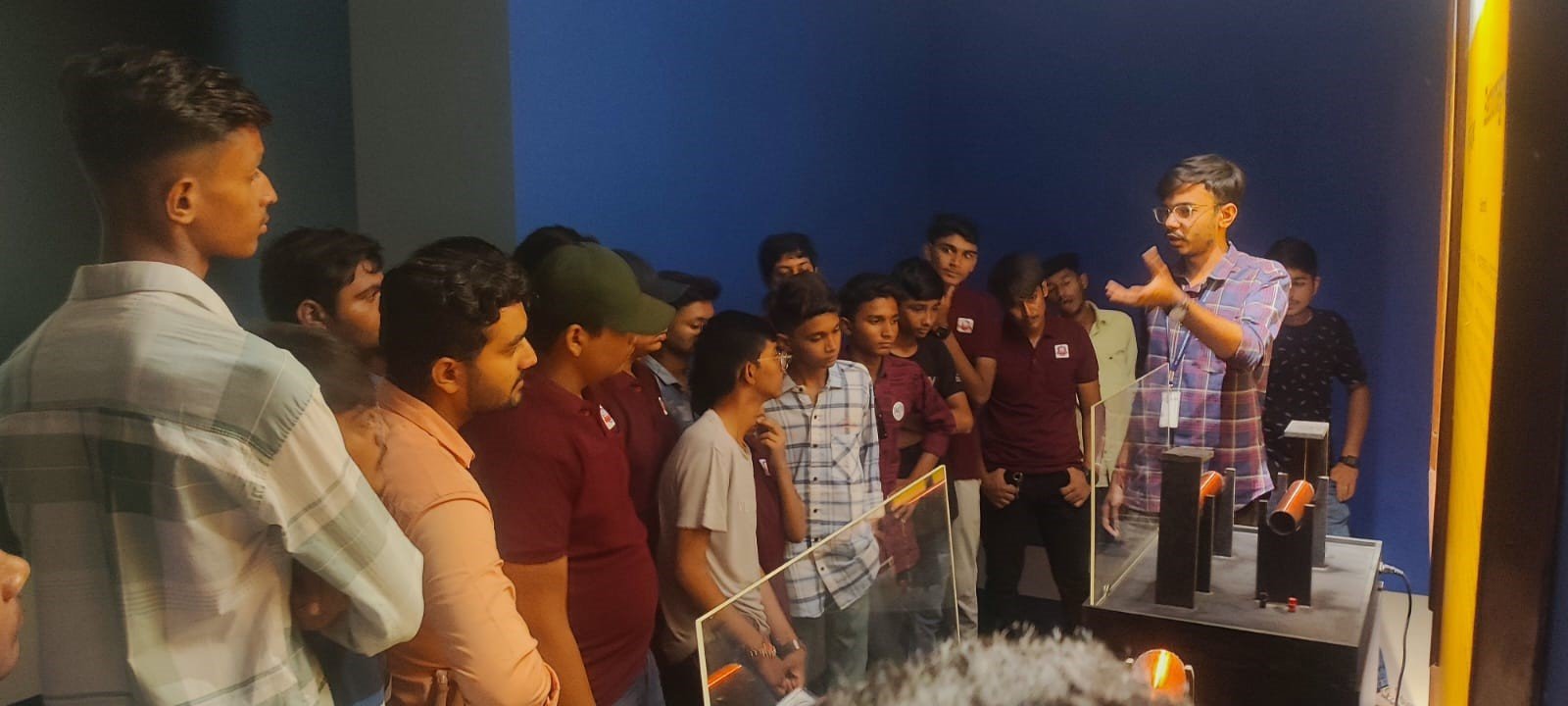

Industrial Visit at Regional S

This Center will provide outdoor accessions like animatronics dinosaurs, science-theme-based toy trains, nature exploration tours, motion simulators, portable solar observatories, and others.

We can see the aquatic ecosystem which includes 3D models of aquatic animals, coral stations, marine life experience through VR short films, formation of earth living habitat, biology tree and evolution of species, grassland and wetlands habitat, history of electro mechanics and the great scientists who contributed to this field along with the explanation of different 3D models and equipments, information on famous scientists who were awarded the Nobel Prize in the ‘Nobel Hall’, history and growth of automobile industry through live display models, as well as different models of aircraft, sailboats and steamships with explanations on its parts used.

Industrial Visit at Trushape P

Trushape Precision Castings Pvt. Ltd., established in 2000 in Bhavnagar district of Gujarat State of India, manufacturing Ferrous & Non-Ferrous Investment Precision Castings (Feinguss) by the Lost Wax process has carved a niche for itself as the manufacturer of Quality Investment Castings.The manufacturing facility is most modern and designed to produce state of the art castings, conforming to most international standards and product-specific standards. With exports to Germany, Belgium, Denmark, Italy, Spain, UK, Colombia (for Investment Casting products) and USA, Singapore, Laos, Nepal, Cambodia, Afghanistan, Somaliya, Uganda, Pakistan (for Prosthetic and Orthotic products),ready to assemble components (OEM), sub-assemblies and assemblies.

- Mechanical Engineering (UNDER GRADUATION)

- Overview

- Mission Vision

- Program Outcome

- Laboratories

- Faculty

- Student Corner

- Placement

- Achievement

- Our Projects