An Industrial Visit to NHSRCL

Acknowledgement

We are thankful to our honorable Principal, Dr. H. M. Nimbark and Head of the Department Dr. V.D. Ujeniya and our faculties who have fulfilled the need of Industrial visit to “the National High Speed Rail Corporation Limited a Geotech laboratory “and “Sardar sarovar dam” for the students of Gyanmanjari Institute of Technology.

We are thankful to NHSRCL GEOTECH LABORATRY, for sharing the information about Geotech and its need and also to allow us to have a visit to well-known laboratory

Information

First of all, Dr. V.D. Ujeniya informed students the importance of industrial visit and ho it can be helpful to gain technical knowledge. Prof. Ravi Sachapara and Prof. Vimal Jogi were there as a responsible faculty to impart their knowledge to the students.

The laboratory is considered as Asia’s biggest Geotechnical Laboratory and has generated employment for an about 900 (500 at field and 400 at laboratories) persons including Engineers, Technician and skilled laborers. This lab is equipped with the state-of-the-art investigation equipment. The facility can conduct 3500 tests per day through 20 geotechnical engineers and 188 lab technicians.

During the training, the students were familiarized with the instruments being used for various geotechnical investigations. Besides lectures, field tests like Plate Load test, Pile load test to determine the soil characteristics through laboratory testing are also demonstrated. First batch of 35 students from Sardar Vallabh Bhai National Institute of Technology (SVNIT) Surat have already received training in this facility.

Then After Visit to Sardar sarovar dam was conducted in which all the information regarding the dam its infrastructural facilities and technical components were assisted. The visit was for 2 days so students were allowed to stay in hotel near the Baroda city. Along with technical knowledge students had lot of fun and good interaction with faculties too. They also gained the managerial skills from the trip.

Industrial visit at Court foun

|

|

GYANMANJARI INNOVATIVE UNIVERSITY GYANMANJARI DIPLOMA ENGINEERING COLLEGE. SIDSAR ROAD, NEAR ISCON ELEVEN, BHAVNAGAR – 364001, GUJARAT, INDIA.

Civil Engineering Department |

Industrial Visit at Court Foundation Work, Near ISCON Eleven, Opp. GMIU. For Degree 5th and Degree 7th Semester Students

Project Title : Industrial Visit at Court Foundation Work, Near ISCON Eleven, Opp. GMIU.

Location : Court, Near ISCON Eleven, Opp. GMIU, Bhavnagar.

Date : 11th October, 2023.

Arranged by : Prof. Gautam Zadafiya and Mr. Gaurang M. Chauhan, Civil Department Staff.

Description about work:

As GMIU Traditional Routine one Industrial Visit arranged near GMIU campus by Prof. Gautam Zadafiya and Mr. Gaurang M. Chauhan, Civil Department Staff for Degree 5th and Degree 7th Semester Students and add one more experience in to do list during learning with below learning outcomes.

Learning Outcome:

- Raft foundation work area about 65 x 65 Sq. mt.

- Beam Column heavy reinforcement detail work capable up to G+9 building.

- Selection of Raft foundation based on Soil Condition.

- Mobile RMC plant at site capacity up to 36 cu. mt. Per hour.

Regional Science Center, Bhavn

|

|

GYANMANJARI INNOVATIVE UNIVERSITY GYANMANJARI DIPLOMA ENGINEERING COLLEGE. SIDSAR ROAD, NEAR ISCON ELEVEN, BHAVNAGAR – 364001, GUJARAT, INDIA.

Civil Engineering Department |

Industrial Visit at Regional Science Centre, Bhavnagar.

Project Title : Industrial Visit at Regional Science Centre, Bhavnagar.

Location : Regional Science Centre, Bhavnagar.

Date : 4th September, 2023.

Arranged by : Prof. Chirag Parmar.

Acknowledgement

We are thankful to our honourable Principal, Dr. H. M. Nimbark Sir and Head of the Department Prof. Ravi J. Sachapara and our faculties who have fulfilled the need of Industrial visit to “Regional science centre Bhavnagar” for the students of Gyanmanjari Innovative University.

We are thankful to “Regional science centre” member for sharing the information about “Regional science centre” and its need and also to allow us to have a visit to well-known laboratory.

Description about work:

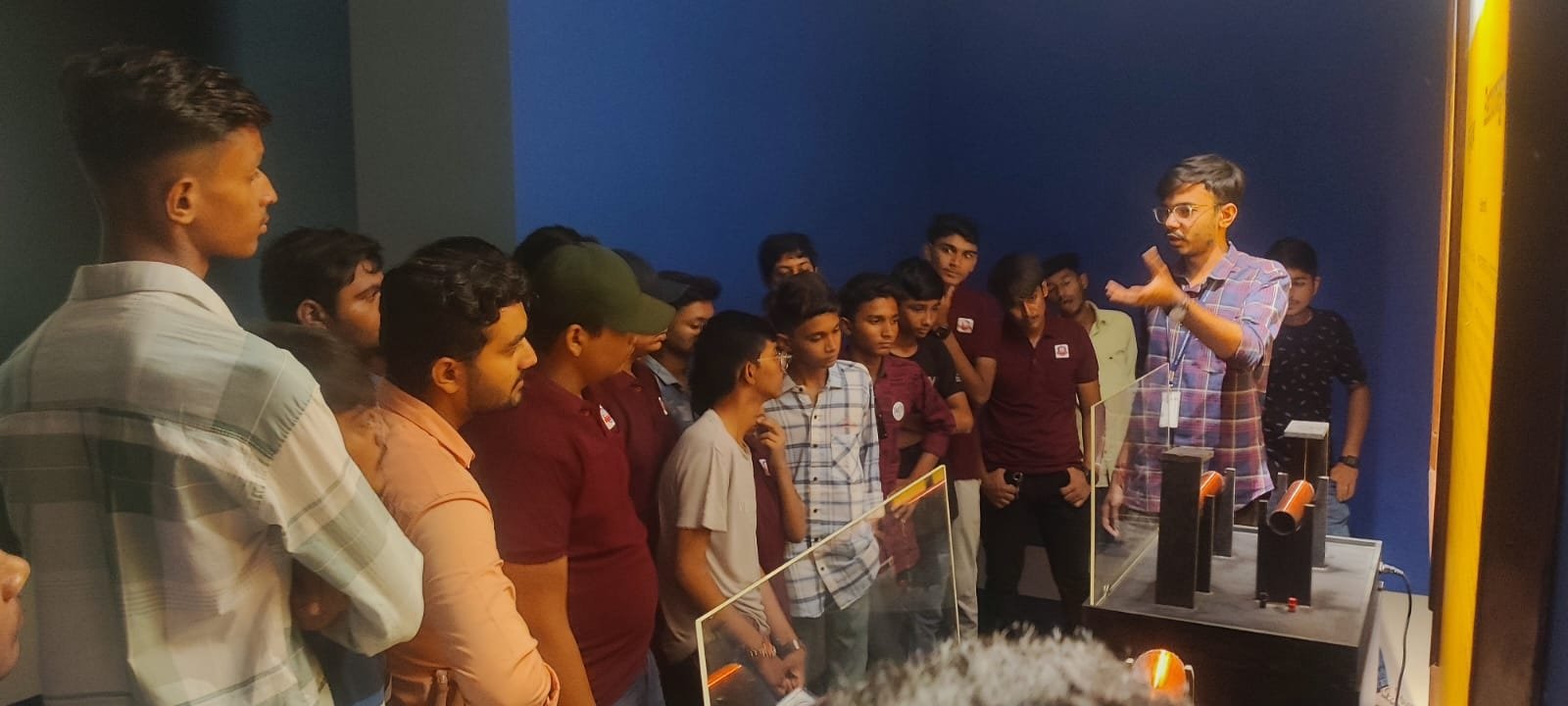

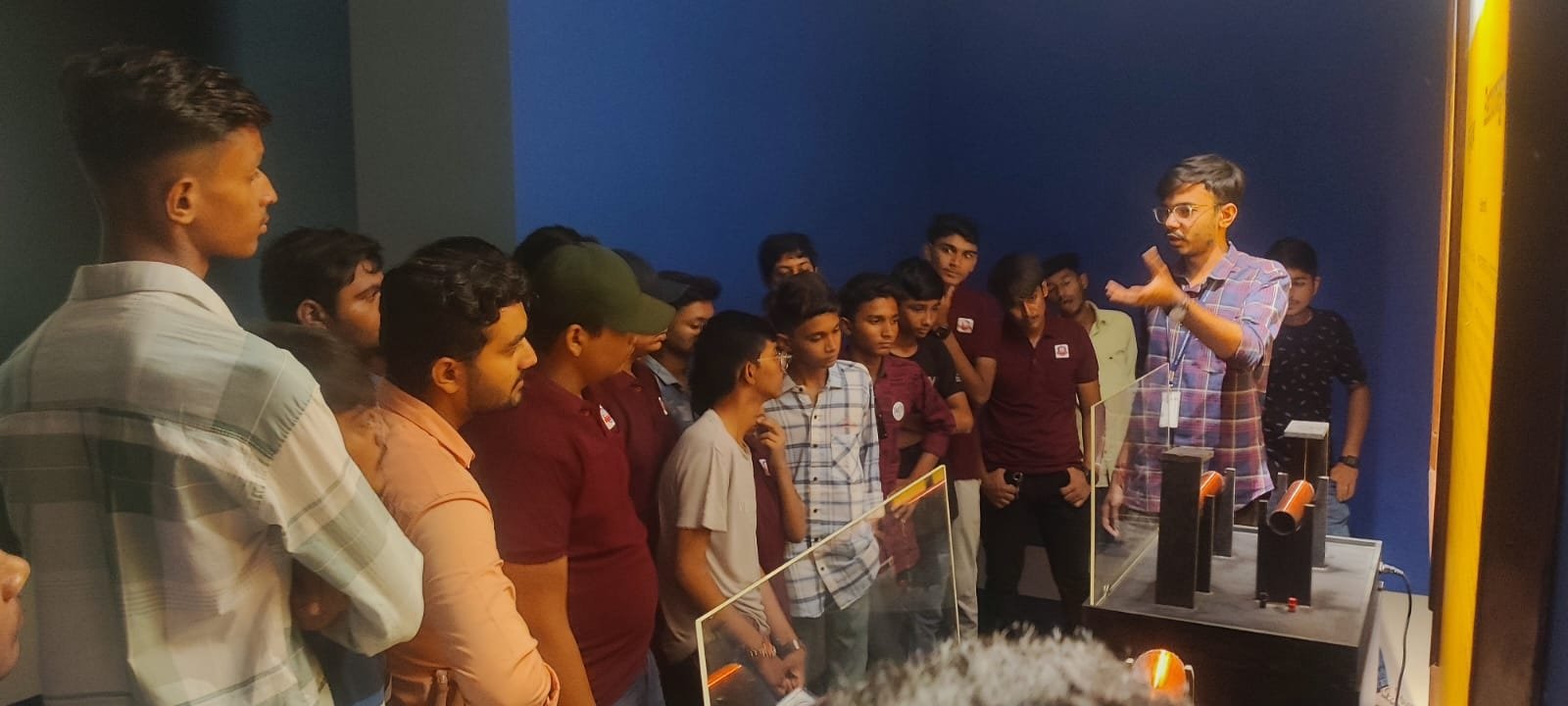

First of all, Prof. Ravi J. Sachapara informed students the importance of industrial visit and who it can be helpful to gain technical knowledge. Prof. Vimal Jogi was there as a responsible faculty to impart their knowledge to the students.

As per our Gyanmanjari Innovative University College tradition we organized an industrial visit for diploma 1st semester Civil, Mechanical and Chemical Engineering students on 4th September 2023.

The regional science centre, Bhavnagar is an innovative hub for science learning and appreciation platform to engage, educate and empower the next generation learners in the cutting edge of science and technology.

Major attractions that we seen in this visit is 5 zone gallery:

- Marine aquatic gallery

- Biology science gallery

- Automobiles gallery

- Electro mechanics gallery

- Nobel prize ( physiology or medicine ) gallery

This Centre will provide outdoor accessions like animatronics dinosaurs, science-theme-based toy trains, nature exploration tours, motion simulators, portable solar observatories, and others.

We can seen the aquatic ecosystem which includes 3D models of aquatic animals, coral stations, marine life experience through VR short films, formation of earth living habitat, biology tree and evolution of species, grassland and wetlands habitat, history of electro mechanics and the great scientists who contributed to this field along with the explanation of different 3D models and equipments, information on famous scientists who were awarded the Nobel Prize in the ‘Nobel Hall’, history and growth of automobile industry through live display models, as well as different models of aircraft, sailboats and steamships with explanations on its parts used.

Industrial Visit 07-05-23 (ADA

Industry Profile:

Company Name: Mundra Port & Special Economic Zone Ltd.

Address: Adani House, Nr. Mithakhali Circle Navrangpura, Ahmadabad, Gujarat. PIN Code: 380009.

Phone: Tel +91 79 2656 5555, Fax +91 79 2656 550

Homepage: www.info@adani.com

Work profile: Natural gateway for the cargo hubs functioning in the Northern And Western states of India as well as the NCR.

About Udaan:

Under this project exposure tours are organized where in school/college students are given a chance to visit the Adani Group facilities such as Adani Port, Adani Power and Adani Wilmar refinery at Mundra, Hazira, SVPI Airport Ahmedabad, Dahanu, Kawai, Tiroda, Dhamra, Gangavaram, Krishnapatnam and Katupalli to get an insight into the large-scale business operations and thus get inspired to dream big in life. The exercise stimulates the young minds to dream big and help them become entrepreneurs, innovators, and achievers of tomorrow, and thus play an active role in the process of nation building.

About Visit

The technical visit to Adani Mundra port started at 6th May 2023 at 12:15 am from GMIT Bhavnagar. There were one bus containing total 53 students (From Civil & Mechanical Department) and 3 faculties (Prof. Vimal H. Jogi , Prof. Radha S. Dodiya and Prof. Rohan J. Padhaya).

The private buses were boarded up to Rajkot. The buses reached Rajkot around 5:00am than from there the buses from Adani were taken up to Mundra port. The buses reached Adani Shanti vihar around 11:30 am. The students were allocated specific rooms and then 1:00pm lunch was provided later.

After lunch there was a visit to Adani Wilmar and Adani Port.

Visit 1 Adani Mundra Port

An infrastructural marvel, the mega port at Mundra is a major economic gateway that caters to the northern hinterland of India with multimodal connectivity. The deep draft, all-weather port is the largest commercial port in India with state-of-the-art infrastructure, Largest Coal Import Terminal which gives faster cargo evacuation and minimal turnaround time.

The multi-purpose terminals contain nine berths of a total 1.8 thousand meters long with alongside depths ranging from 9 to 16.5 meters. Berth 1 is 275meters long with alongside depth of 15.5 meters and can accommodate vessels to 75 thousand DWT. Berth 2 is 180 meters long with alongside depth of 13meters and can accommodate vessels to 30 thousand DWT. Accommodating vessels to 60 thousand DWT, Berths 3 and 4 are each 225 meters long; Berth 3has alongside depth of 14 meters, and Berth 4 has alongside depth of 12 meters. Berths 5 and 6 are each 250 meters long with alongside depth of 14 meters, and both can accommodate vessels to 150 thousand DWT. Berths 7 and 8 are each175 meters long with alongside depth of 12 meters and can accommodate vessels to 40 thousand DWT. The Barge Berth is 80 meters long with alongside depth of 6 meters and capacity for vessels of 2500 DWT.

The Mundra Port offers 21 closed dockside warehouses with capacity for 137thousand square meters to store wheat, sugar, rice, fertilizer and fertilizer raw materials, and deoiled cakes. The port offers 880 thousand square meters of open storage for steel sheets, coils, plate, clinker, scrap, salt, coke, bentonite and coal. An additional 26 thousand square meters of open storage is available alongside the railway. The port also offers a wheat-cleaning facility with capacity to handle 1200 metric tons per day and a rice-sorting and –grading facility that can handle 500 metric tons per day.

The Port of Mundra is planning several additions and improvements. Twothermal power plants are under construction that will produce over 8600megawatts. A new terminal site is proposed to be located about ten nautical miles west of the current terminals at the Port of Mundra. The terminal will eventually contain three deep-water offshore berths and two sets of stack yards for coal, iron ore, and other dry bulk cargo.

The marine infrastructure at Mundra Port consists of ten (10) berths for handling dry bulk &break bulk cargo, three (3) berths for handling liquid cargo, six (6) container berths including a Ro-Ro berth, three (3) mechanized import cargo berths and 2 single point moorings for crude oil imports. The mechanized import cargo berths can handle vessels with maximum draft of 19meters and other berths can handle vessels with maximum draft of 17 meters. The SPM facility offers a draft of 32 meters.

Heaps of coal was alongside the road. There was PORT based SEZ which was spread in 15000 hectares. There were open stock yard for MINERALS & Closed Stock yards for FERTILIZERS & GRAINS etc. Jetty was divided as DRY CARGO, CONVEYOR BELT for COAL & PIPELINE for Liquid crude i.e. VLCC (Very Large Cargo Container) & ULCC (Ultra Large Cargo Container).

Visit 2 Adani Wilmar Limited

Adani Wilmar Limited (AWL) is a joint venture incorporated in January 1999between Adani Group, the leaders in International trading & Private Infrastructure with businesses in key industry verticals - resources, logistic sand energy. The group was created with a vision of ‘Nation Building’ by developing assets of national economic significance. Wilmar International Limited - Singapore, Asia's leading Agri-business group & its business activities include oil palm cultivation, oilseed crushing, edible oil refining, sugar milling and refining, specialty fat, biodiesel and fertilizer manufacturing and grain processing. It has over 450 manufacturing plants and an extensive distribution network covering China, India, Indonesia and some 50 other countries.

In the refining process, the first step was BLEACHING. Under bleaching, the major impurities were removed from the oil which deteriorated the color of the oil.

The bleached oil was then FILTERED and the heavy impurities were taken out from it. Finally, the strong smell of crude was to be eliminated to get the final product. Thus the DEODERIZATION of oil was done. This process removed all the impurities which were deteriorating the odor of oil.

At 250-270 degrees Celsius, the oil was made to pass high vacuum pressure which refined it completely. Fatty acids, which were removed while deodorizing, were sent to the soap industry.

Other impurities which were extracted from the crude while bleaching and filtration were sent to incense stick making industries. And thus, no part of the crude was wasted at any of the step in the refining process.

After knowing refining, students were taken to the packaging section of the oil industry. Uniform conveyer belt system that connected the whole packaging process into one. The oil bottles were filled and entered into the station where first they were shut with bottle caps. And then they were further passed to put on the Label. Afterwards, a packaging machine packed 36 bottles each at the same time into three different boxes i.e. 12 bottles in one box. Finally, the boxes were sealed with tape and were further sent for storage or export.

The whole process was fully automatic and was working on PLCs. The PLCs made the work so easy that not a single human was involved in this process at any instance of time. ADANI WILMAR packaging unit has 6 cold storage units in which the temperature is slowly decreased up to -5 degree Celsius. The fully equipped Adani Wilmar can produce 6000-7000 liters of oil/hour in the industry.

The students have also viewed the Jetty and various ships from the bus. The students have also visited Shantinath Mahadev Temple during evening prayer followed by dinner and were engaged in fun games in the campus later.

Next day 8th May we were going toward Adani power.

Visit 3 Adani Power Plant

The Mundra Thermal Power Project was conceived to provide power for the captive consumption of APSEZ in Mundra. Thereafter the vision and the capabilities of the promoters has made Mundra Power project the largest single location Coal based Thermal Power Station in India and one of the top five in the World. All the nine units of Mundra power plant have been commissioned one after another in shortest possible time of 33 months. Capacity - 4620 MW (5 X 660 MW + 4 X 330 MW). Largest single location private coal-based power plant in the world. Adani Power created history by synchronizing the first super-critical technology based 660MW generating unit at Mundra.

This is not only the first super-critical generating unit in the country but also the fastest project implementation ever by any power developer in the country with synchronization within 36 months from the inception.

The Phase III of the Mundra Project, which is based on supercritical technology, has received ‘Clean Development Mechanism (CDM) Project’ certification from United Nations Framework Convention on Climate Change (UNFCCC).

This is the world’s first thermal project based on supercritical technology toget registered as CDM Project under UNFCCC.

The power plant supplied 4620 Mega Watts of energy. Out of these 2000 is supplied to HARYANA, 2000 to GUJARAT government, & 620 is internally used. It uses HVDC (High Voltage DC) for transmission to HARYANA as it is a long distance transmission it is to be converted into DC first & then it is again recovered. Live status of frequency and power generated was available in the control room.

The visit was ended after lunch and feedback to the officials. The buses havestarted from Mundra around 1 pm and reached Rajkot at 7 pm. Then after we reached Bhavnagar around 1am by private bus.

The visit was truly professional and well managed till the end. The staff and students were thankful to the Adani foundation and GMIT college management for granting the permission for the visit.